Technical Data

HEATING

A controlled uniform temperature of approximately 250°F is required to soften PVC conduit. PVC conduit may be reheated and reformed, if necessary, without damage to the material's properties. Schedule 40 and 80 PVC conduit, using the procedure outlined below, can be field formed easily with no deformation. Ducts, such as “EB” (encased burial) must be carefully controlled to prevent deformation and swelling of the very thin walled material. Very tight radius bends of any style or size pipe are difficult to achieve and may require controlled manufacturing conditions. EZ BEND® PVC Benders can easily and quickly make field bends, sweeps, and offsets.

The correct forming temperature can be determined by opening the cover long enough to lift one end of the conduit from the rollers. When the material deflects readily without resistance and has a glossy appearance to it's surface, it is ready to remove and form. Although air temperature and wind conditions have an effect on the heating time, this rule of thumb may be applied when using an EZ BEND® PVC Bender: Allow approximately 30 seconds time for each ½ ” of pipe diameter in order to reach proper forming temperature. (½” Diameter = 30 seconds, 2” Diameter = 2 minutes to reach bending temperature.)

FORMING

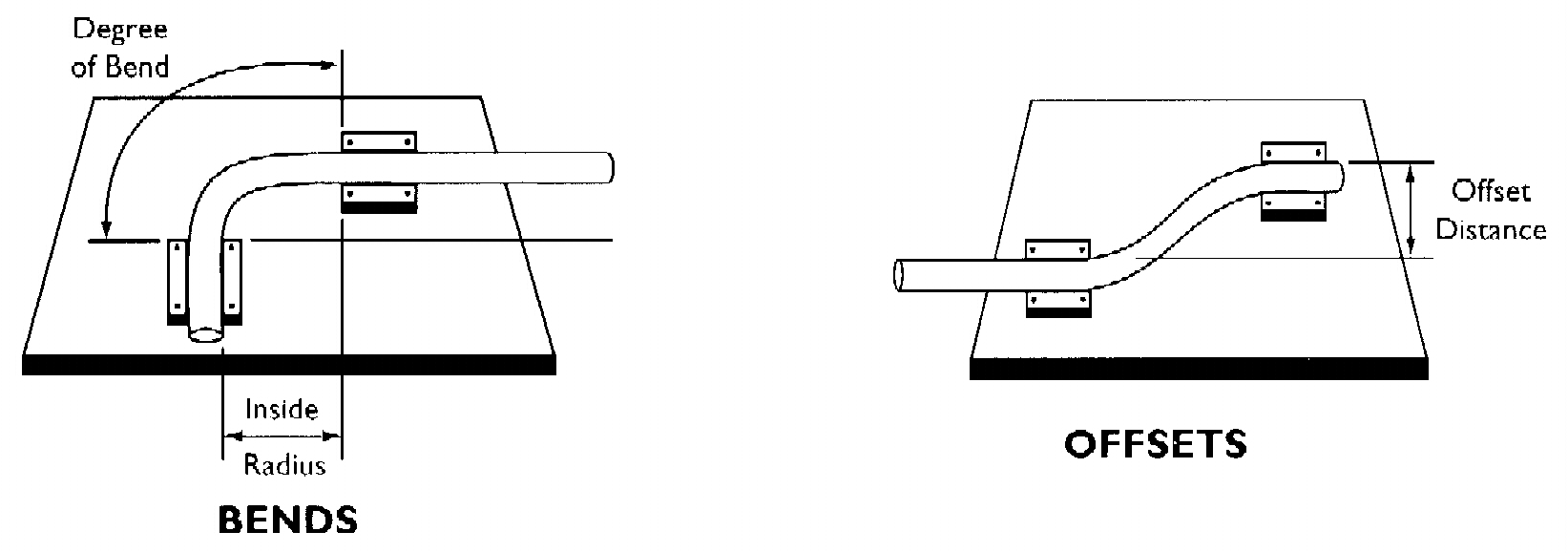

Conduit sizes ½ ” through 1 ½ ” diameter, do not require bending plugs because they normally do not crimp, flatten or deform during the bending process. Simply rotate the material in the EZ BEND® unit until softened. The softened conduit may then be formed and installed in place. To quickly set the bend or offset, wipe down the piece with cold water. Should several identical bends be required, or a specific degree of bend or radius is necessary, a simple wood form similar to the example pictured below is suggested.

PREVENTING DEFORMATION

Conduit and duct 2” diameter and larger may crimp, flatten, or deform during the bending process. EZ BEND® Bending Plugs help eliminate this problem. Select the proper size bending plug and insert one into each end of the conduit before heating. The retained air will expand during the heating cycle and the resulting pressure will adequately support the walls of the conduit to prevent deformation when making a bend. Adapters slip over the plugs and are provided with our Bending Plug Kits for half sizes and for bell-end pipe. Bends tighter than four (4) times the diameter of the pipe equaling the inside radius of the bend (4 X Dia = Inside Radius) are difficult to achieve without controlled manufacturing conditions.

GENERAL INSTRUCTIONS:

1. Place the EZ BEND® unit on a secure, dry surface. Keep flammable and combustible materials away from the area when operating the PVC Bender.

2. Connect the unit to an adequate power supply with GFCI protection. Allow approximately 90 seconds for the full heat development of the unit.

3. Place the conduit on the unit’s rollers, close the cover, and slowly rotate the material until it has softened. If necessary, move or slide the pipe back and forth in the bender to evenly heat the length of the pipe that is to be bent.

4. Avoid burns by wearing the proper heat resistant gloves; always plug the unit into a GFCI protected power source, and disconnect the unit during prolonged work delays. Think Safety First!

Example of a form or jig that can be made to make repetitive bends or offsets. We suggest that a non-heat conducting material, such as wood, be used.

Questions? Contact us at pvcbend@ezbend.com or call us at (800) 782-3009

Bradshaw Mfg., Inc. 9627 Clinton Road, Cleveland, OH 44144-1029

Phone: (800) 782-3009 · (216) 281-8585 · Fax: (216) 281-8586 · (888) 782-3010 E-Mail: pvcbend@ezbend.com Web Site: www.ezbend.com

Link: For our metal Tube Bender (www.ezebend.com)

Copyright © 1989-2009 Bradshaw Mfg., Inc. / EZ BEND® is a registered trademark of Bradshaw Mfg., Inc. All Rights Reserved.

Last modified: August 14, 2009 We accept VISA and MasterCard.

Incoloy® is a registered trademark of the National Nickel Co.